The Robot Solution? Only If We Fix the Human Side Too

By Roch Nakajima, CMO, Noitom Robotics

We’re all feeling the same pressure: too few people for too much work. It’s tempting to say, “Send in the robots and call it a day.” But if the last decade taught us anything, it’s this: there are no silver bullets in operations—only systems that work together.

Robotics is part of the answer. It’s not the answer.

What’s really behind the “labor shortage”

This isn’t one big gap—it’s a thousand small ones. Night shifts no one wants. Repetitive jobs with high churn. Roles that need three weeks of training for tasks that change every three days. Immigration rules that tighten, then loosen. We keep calling it a shortage when it’s also a mismatch.

Where robots earn their keep—today

The win isn’t replacing people; it’s redesigning work.

- Offload the dull, dirty, dangerous tasks so teams can focus on value and safety.

- Don’t automate the building; standardize one lane. Pick → stage → inspect—then copy‑paste.

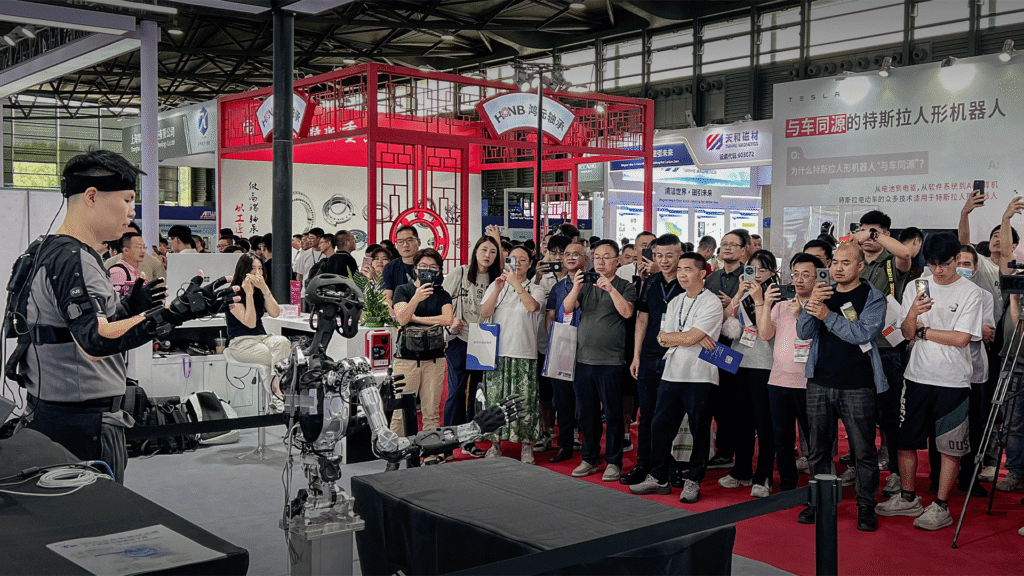

- Add teleoperation backstops so one skilled operator can unblock many robots in real time.

- Capture the right data as you go, so tomorrow’s models learn from today’s work.

On that last point: intelligence isn’t just algorithms—it’s experience. Real‑world, multi‑modal, messy experience. Vision, motion, touch, and context captured together, governed, and made learnable. That’s the data layer that turns hardware into help. It’s why my company’s mantra is simple: we don’t make robots; we make them intelligent—by delivering the data pipelines and teleop infrastructure that embodied AI actually needs.

The quiet killer: hidden costs and slow payback

If you compare wages to a robot’s sticker price, you’ll fool yourself. Integration, safety, training, maintenance, software, cybersecurity—the total cost shows up later, and it’s real. The ROI is there, but it’s earned—not gifted. The right question isn’t “How cheap is the robot?” It’s “How quickly can we turn this into a dependable, observable system that delivers value every day?”

A quick TCO gut‑check I use:

- Scope: Are we automating a task, a cell, or a whole shift?

- Stability: How often do upstream conditions change? (SKU churn, lighting, layouts.)

- Support: Do we own the skills to keep this running—or rely on a single integrator?

- Safety & Trust: Can we prove it’s safe and predictable before we scale?

The social license matters

Autonomy grows in public. That means safety, transparency, and accountability aren’t “phase two”—they’re day one. Deploying learning systems into real workplaces without strong guardrails is a fast way to lose trust and gain regulation. Start conservative, instrument everything, and expand on evidence.

A playbook that works

We’ll close the gap fastest with a hybrid approach:

- Make the jobs better. Raise quality of work alongside wages: safer stations, shorter training, clearer career paths.

- Invest in people. Reskill and upskill for human‑plus‑machine teams—operators who troubleshoot, not just tend.

- Use immigration strategically. It’s the most immediate lever for acute gaps while training kicks in.

- Deploy robotics where variance is bounded. Start with high‑repetition tasks and build outward.

- Instrument the floor. Measure the operator‑to‑robot ratio, interventions per hour, and mean time to recovery. If those trend down, you’re winning.

Human‑in‑the‑loop is not a compromise—it’s the ramp

We learned this from “autonomous” vehicles: the scalable model is human‑in‑the‑loop infrastructure, not magical thinking. Robotics is heading the same way. Design for remote assistance. Capture the intervention data. Feed it back into training. That’s how autonomy actually compounds. It’s also why we’re building end‑to‑end teleoperation and multi‑modal data pipelines—because the path to reliable autonomy runs through great human‑robot systems, not around them.

Why the data layer keeps coming up (and why it’s urgent!)

General‑purpose robots won’t learn from single‑sensor toy datasets. They need synchronized streams—vision, motion, tactile, environment—captured and aligned for training and transfer across embodiments. That’s the work my team is focused on, and it’s why we partner on purpose‑built platforms for high‑quality capture and teleop. If we get the data right, we shorten the distance between a human demonstration and a robot you can trust.

Bottom line: the future isn’t robots or people—it’s robots with people, designed well. Let’s stop asking if machines can “solve the shortage” and start asking how fast we can build teams where each side makes the other better.

Get in touch

Curious about pilots, research collaborations, or custom integrations?

Email us at: contact@noitomrobotics.com